Search

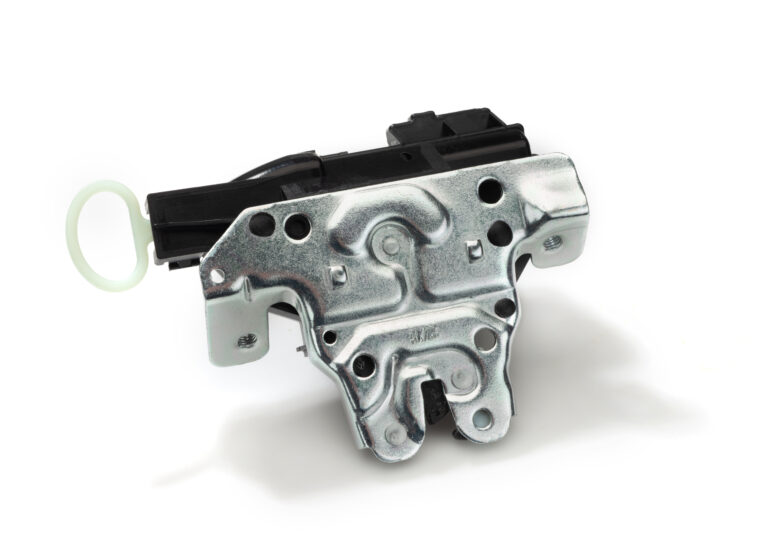

Precise and high quality injection moulded parts

for every industry

When it comes to plastics technology, we are in our element, because this is where we can bring the full range of our capabilities to bear in the close interaction between development, design, toolmaking, injection moulding and assembly. Benefit from our extensive experience in processing technical high-performance plastics into customised products for the automotive, on-highway, off-road and medical technology sectors.

Plastics technology

We specialise in the production of injection moulded parts using single and multi-component processes, hybrid parts as well as simple and complex module assembly. Whether prototype, individual part or series part – whether small, medium or large series: we fulfil individual requirements at the best possible price-performance ratio.

- Plastic injection moulding

- Hybrid components

- Prototyping

- Module assembly

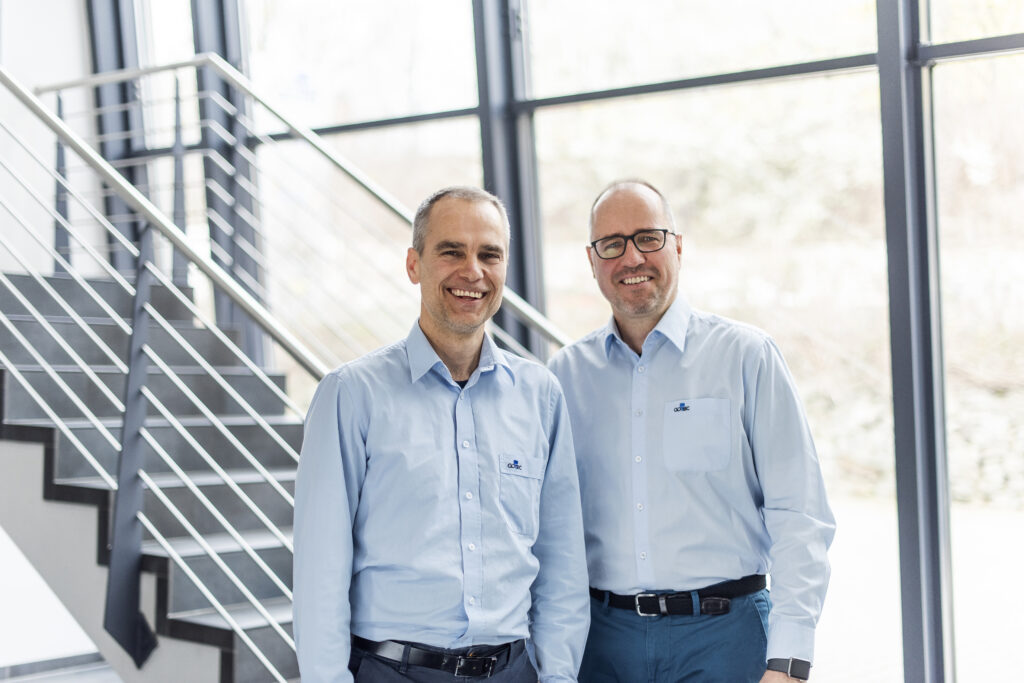

We know your industry. And we know

plastics technology.

Many years of experience, market knowledge and constant further development make the difference. Our experts in plastics technology are at your side right from the development phase to ensure high-quality end products. Our globally standardised quality management system is certified according to DIN ISO 9001 and IATF 16949. This means that we meet the highest production standards. To complete our range of services and provide you with the best possible support, we also offer comprehensive project management as well as holistic solutions in the area of production takeovers and the relocation of moulds.

Quality

Our processes, qualified according to ISO standards, ensure consistently high product quality.

Transparency

On-time delivery, cost-effectiveness and trust: Our project managers are always in close contact with you.

Full-Service

We offer added value that goes beyond the mere production of parts and the service of coating.

Contact us