Search

Specialist for bonding agent coating

of rubber-metal/plastic parts.

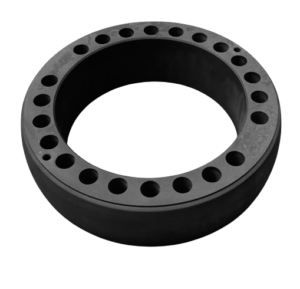

Rubber-metal or rubber-plastic compounds are found in many vibration-damping parts, such as bearings and buffers or seals, and are primarily used in industry and in the automotive or commercial vehicle sector. For example, there are more than 50-100 rubber-metal compounds in passenger cars. These not only have to meet very high mechanical requirements, but also must be able to resist enormous dynamic loads and environmental influences, as well as being reliable and durable. The quality of the connection makes all the difference to performance and service life. It is therefore advisable to rely on the know-how of specialists in the field of bonding agent coating.

First class bonding agent coating for

more durability

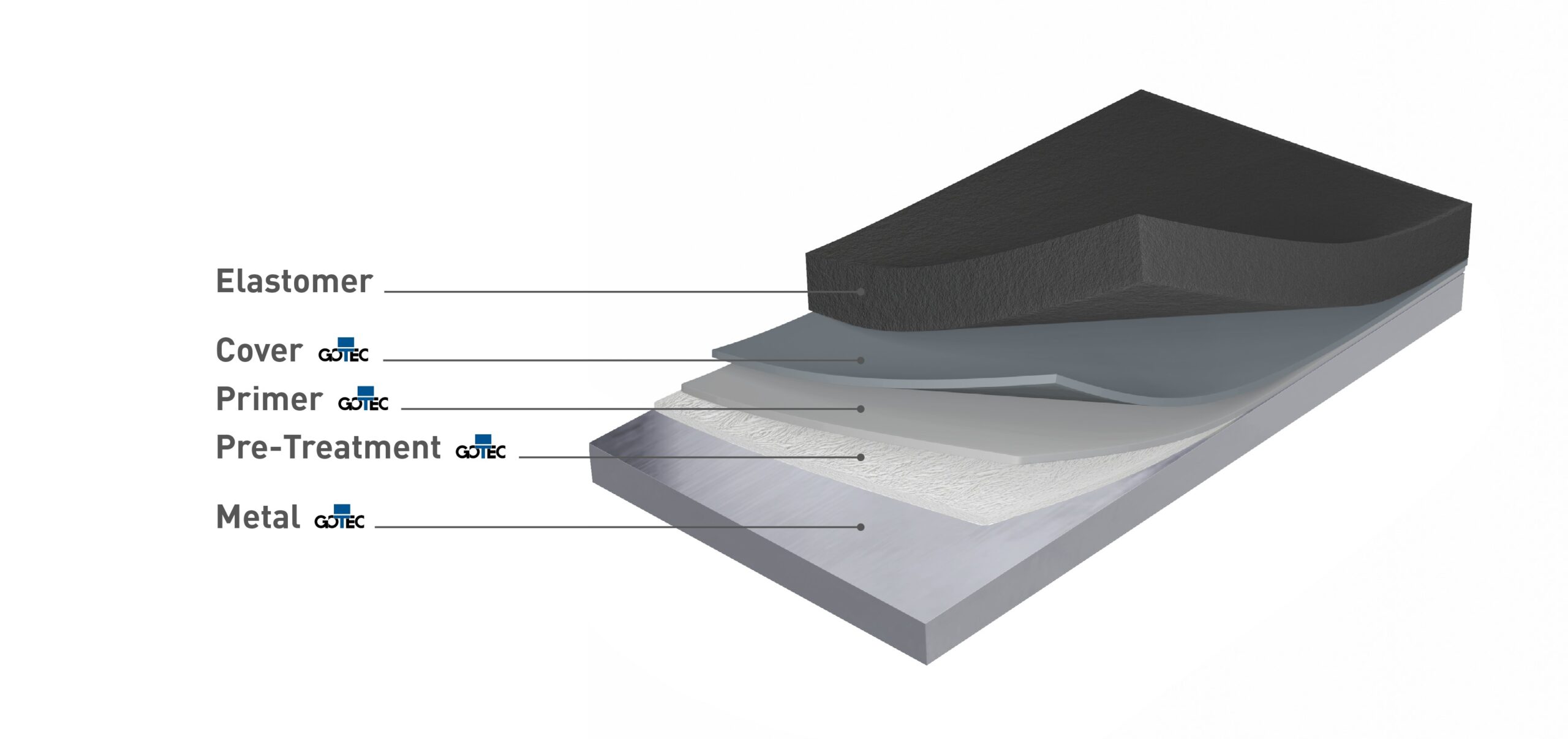

To enable a long-lasting bond of hybrid components, the surface of the component must first be prepared in a multi-stage process. Professional pretreatment in the form of cleaning, enlargement of the bonding surfaces and activation is recommended for this. The bonding agent can then be applied.

The bonding agent is a binding agent that can be water-, silicone- or solvent-based and fulfils the function of creating a strong and durable bond between the elastomer (rubber) and the substrate (metal or plastic). This creates a component that combines the positive properties of both elements. While the metal, for example, serves as stabilisation and fastening and withstands a wide range of loads, the elastic moulded part made of rubber provides optimum sealing or fulfils damping and suspension functions. Ideally suited for a wide variety of applications in the automotive industry as well as in almost all industrial sectors. Thanks to our many years of experience in the field of bonding agent coating and our in-house mechanical engineering department, we have the necessary expertise to find the best solution for your individual requirements.

Depending on the customer’s requirements, we apply the bonding agent using a wide variety of common technologies.

- chain-on-edge coating

- hand coating

- round table coating

- roll coating

- flat bed spray coating

- dip coating

- dip & spin coating

- tumble spray coating

- electrostatic coating

Bonding systems

We use bonding systems from all well-known manufacturers, including Parker Lord, Dupont, H.B. Fuller or Wacker. We apply in a one-layer or two-layer system. Conventional bonding systems consist of two components (layers), the primer and the cover. They are especially suitable for applications that have particularly high requirements in terms of dynamic stress and corrosion resistance.

In the first step, a primer in the form of Chemosil 211 is applied to the metal part. In order to guarantee adhesion between the metal and the subsequent cover, a layer thickness of approx. 5-15µm is applied. The cover is then applied with Chemosil 411NL. Here, the layer thickness is between 15-40µm. When applying bonding agents, layer thickness specifications should always be observed to ensure adhesion. In line with our high quality standards, we continuously check the layer thickness and the entire process chain to ensure first-class results.

GOTEC - Quality leader for bonding agent coating

GOTEC Group is the global specialist for surface finishing and bonding agent coating for rubber-metal parts. With the large number of different application processes of our machines and special systems, we also fulfil individual customer requirements. Outstanding quality is our top priority. We guarantee this through our certified quality management and our own quality standards. Trust in our know-how.

Know-how

We have decades of experience in coating with bonding agents.

Leadership

We are market & innovation leader and partner of the international automotive industry

Performance

We guarantee the highest manufacturing quality at an optimal price/performance ratio.

Contact us